Brand new Developments in Material Fabrication

Metal fabrication will be the art of altering one form regarding metal into one more and is also used inside arts and designs, jewellery and weightier applications, for example building staircases, metal hand rails, balconies and so forth.

Inside CNC Cutting Chepstow was employed for non-decorative uses, for example making equipment and weapons. Experts consider the techniques found in fabrication techniques as metallurgy. Above the course involving time the types of metals applied has changed just as has our ability to mine and get different metals. Metals come from the earth in the form of pépite. Typically iron and even steel are used to help make cars, trucks and even aeroplanes whilst platinum and silver are used in electronic digital circuitry.

Metal manufacturing to this working day remains a substantial in-demand trade plus there are a lot of college and apprenticeships that provide training inside this area.

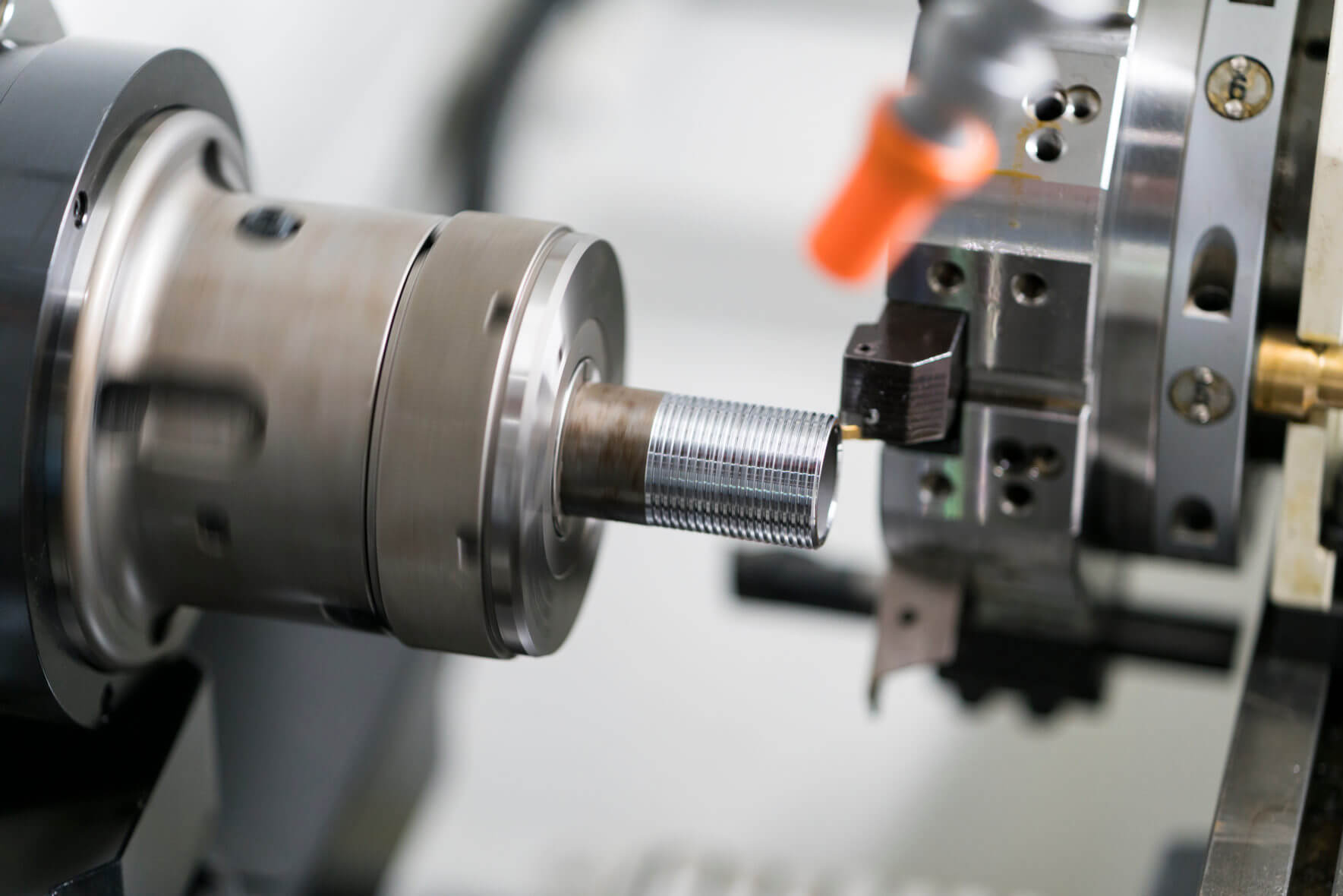

A number of techniques are applied in the fabrication procedure including sawing, shearing, chiselling and working for bending. Welded, adhesives, fasteners and even riveting are most commonly used intended for joining and binding metal pieces collectively. Welding remains the best technique for metallic fabrication, where the formed or made parts are constructed and welded directly into place.

Custom Bed sheet Metal Manufacturing

Custom made sheet metal manufacture is commonly employed in the ventilation, air conditioner and heating companies. With the help of computer aided plasma cutting and computerized layout approaches, shops can fabricate one part or thousands of similar parts required to be able to build the most effective heating, ventilation plus air conditioning methods for residential, professional and industrial sectors.

One of typically the most common methods of cutting metal is by shearing using special band saws designed intended for the idea with excess hard blades plus a mechanism for even cutting. Forms of saws employed include cut-off saws, or chop saws, and miter saws Very large sections of steel can be cut using torches.

Plasma and laser cutting dining tables are frequently applied. Water jet cutters, may also be widely utilized. Plate steel is usually placed on the table where a computer programmed handles the cutting process. Fabrication of strength steel by flat screen and laser reducing introduces robots to move the trimming head in 3 dimensions around the particular material to end up being cut.

When it comes to forming hydraulic brake pushes are the most often used. The slice plate is positioned in the press plus a v-shaped expire is pressed a new predetermined distance in order to bend the plate in order to the desired angle. Sometime wing brake systems and hand powered brakes are introduced

Tube bending equipment have specially designed dies and mandrels to bend tube sections without kinking them.